Industry

In March 2021, the government of Nepal happily announced that the country had become self-reliant on a multitude of products such as milk, tea, sugar, flour, spices, meat, fish and green vegetables.

Presenting an impressive list of products made in Nepal, the government’s Department of Industry announced that the country had become self-reliant also on shoes, wood, furniture, soap, tobacco products and alcoholic beverages in addition to conductors, and at least two types of pipes.

Although not completely self-reliant, the pharmaceutical industry too is said to be doing good, with the country’s nearly 100 pharma companies exporting pharmaceutical products worth nearly 9 million US dollars in 2019, according to UN’s Comtrade database.

And such news came at a time when industrialists and consumers alike seemed worried at ever-increasing volumes of import of food, automobiles and so on - and the draining of the country’s foreign currency reserves to purchase all that.

One year later, however, concerns remain as Nepal is still forced to import many essentials such as rice, the staple diet, and goats during festivals like Dashain – let alone machinery, laptops and the ubiquitous mobile phones.

The list of essential and luxury commodities that Nepalis buy from foreign countries goes on and on. Last year, Nepalis spent Rs. 1197 billion on foreign goods, while they only sold goods worth Rs. 98 billion. Such huge import with a much lesser export has been leading to a massive trade deficit for years.

What then would be the solution?

The obvious answer would be this: Developing the country’s industrial sector and making it so robust that reliance on foreign goods gradually begins to drop. That’s precisely where the unique initiative, Make in Nepal, could come into the picture and start making a difference.

The Confederation of Nepalese Industries (CNI)-led initiative is a multi-year campaign that aims to develop the industrial sector by increasing domestic production and consumption of Nepali goods and services. Coincidentally, the government of Nepal too embraced the campaign, incorporating Make in Nepal in its annual programmes and policies, and announcing that the government would make it a decade-long campaign.

So if things move according to the plan, many things will gradually change. Make in Nepal’s primary objectives are to register 1,000 industries annually, increase the industrial share of Gross Domestic Product (GDP) to 22 per cent by 2025, create 150,000 industrial jobs every year, and achieve exports worth 4.6 billion US dollars in the next five years.

But, experts fear that the road ahead may not be easy, and the campaign is likely to face external and internal obstacles, which could come in the way of opening new industries, creating more jobs and reducing reliance on foreign goods.

“We must overcome multiple challenges,” Keshav Acharya, an economist, also senior programme adviser at the Economic Policy Incubator, told NepalMinute. “We don’t have enough raw materials, which we still need to buy from outside. Second, we don’t have the right kind of infrastructure to facilitate rapid industrial growth. Third, our governance is poor and not very accountable which often leads to delays and price hikes.”

Industrialisation in Nepal

Yet the Make in Nepal campaign is here to stay.

Normally, countries across the world start with a dominant agriculture sector, argue some economists. As the economy grows, they say, industrialisation occurs and the economy moves out of agriculture to manufacturing, which generates productivity and output. And when the economy moves to the advanced stages, the service sector starts to blossom.

However, in Nepal, the country jumped into the service sector without establishing a stronghold of industrialisation, according to CNI’s campaign booklet.

The process of modern industrialisation started in the country even before World War – II, when Biratnagar Jute Mills was established. In the 1950s and 1960s, along with sugar mills in Biratnagar and Birgunj, Janakpur Cigarette Factory, and Bansbari Shoes Factory were established. Carpet, garments and a variety of medium- and small-scale industries flourished in the 1980s. But it was only after the government adopted economic liberalisation policy in the 1990s that the country shifted into a trading environment.

Overall growth nosedived during the decade-long Maoist insurgency that took a heavy toll on the country’s economic and industrial activities between 1996 to 2006. Aftershocks remained in the aftermath too with industries struggling to bounce back during the long transition that ended only after the promulgation of the Constitution of Nepal in 2015. Then came the devastating earthquakes that claimed the lives of 9000-plus people and destroyed or damaged over a million houses and ancient monuments.

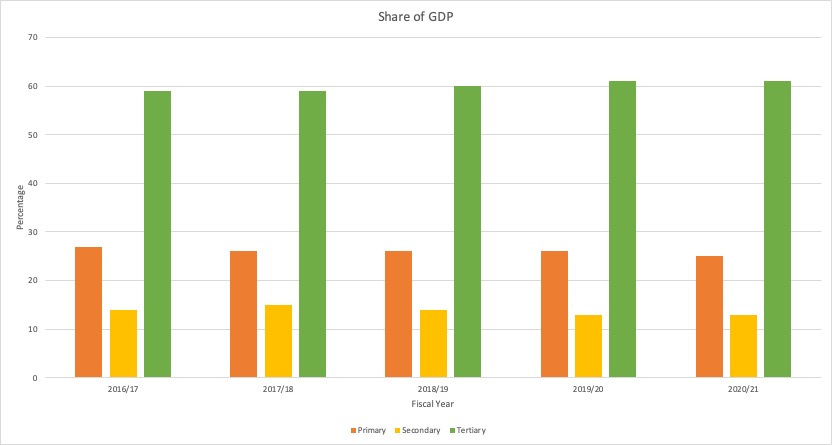

Post-earthquake reconstruction activities gave a new lease of life to the construction sector. Yet they didn’t quite help the other vital industries to take shape or grow. In the fiscal year 2020-2021, the tertiary or service sector contributed 61 per cent to the country’s Gross Domestic Product (GDP), while the secondary and primary sectors contributed 13 per cent and 25 per cent, respectively, according to the Central Bureau of Statistics.

Specifically, the manufacturing sector’s contribution to Nepal’s Gross Domestic Product (GDP) was over 10 per cent until two decades ago. But gradually, it has gone down to less than 6 per cent.

“It is a pathetic situation. It shouldn’t have happened, but it happened,” economist Acharya told NepalMinute, attributing the loss majorly to the fall of the ready-made garment industry in 2005 after the end of the Multi-Fibre Arrangement. That agreement remained effective from 1974 to 2004, and it restricted the number of textiles and garments that could be exported from developing countries to developed countries.

Meanwhile, the Make in Nepal campaign hopes to turn things around and help make things better. Promoters say it’s an attempt by the private sector to reengineer industrialisation in the country. Since its inauguration 15 months ago, the campaign has onboarded 53 new companies. And more than 20 others are joining soon.

The organisation has identified seven pillars, four focusing on production and three emphasising consumption. Nirnaya Bhatta, Director, CNI’s Research Cell told NepalMinute: “As per the back of the envelope calculations, the worth of these 53 industries would be around Rs 200 billion.”

Additionally, they have also managed to bring the government on board. The Ministry of Industry, Commerce and Supply and CNI signed a Memorandum of Understanding (MoU) on June 24, 2021, that recognised the partnership between CNI and the government to implement the “Make in Nepal – Swadeshi Abhiyan”.

External obstacles

While CNI officials believe that they have a “strong vision and goal”, they are sure to face all the issues that every industrialist goes through when establishing a business in Nepal. The two biggest challenges will be to reduce the cost and ensure the availability of a skilled labour force, say experts.

Infrastructure and land prices, the two essentials of the manufacturing sector, they add, are expensive in Nepal. “Land prices in Nepal are much higher than anywhere in South Asia. So, how do you invest?” said economist Acharya.

Government officials agree. Recognising the importance of cost reduction for Nepal’s industry, Narayan Duwadee, Joint Secretary at the Ministry of Industry, Commerce and Supplies told NepalMinute: “To attract foreign investment and create the necessary environment, we need cost reduction. Till then we only have a slogan and nothing else.”

Additionally, there is a huge gap in the labour market of Nepal. Industrialists have told the government that the quality of the human resource available in the market currently and their need is “perfectly mismatched.”

Therefore, to help them, Joint Secretary Duwadee told NepalMinute: “We are going to start an apprenticeship program. In this program, the human resource can be trained to fit the industry. For the first three months, we will pay the basic salary. And the company can train and use them in the industry. Teach them whatever is needed to be taught.”

Furthermore, Joint Secretary Duwadee believes that the unmotivating nature of industrialists is the biggest challenge the Make in Nepal campaign is facing. “Production is painful but it gives sustained happiness."

Internal obstacles

CNI is facing some internal obstacles in their Make in Nepal campaign.

The biggest one for CNI has been that they are not able to present the campaign as a package to the Nepali people.

Director Bhatta told NepalMinute: “CNI does tons of things for industries throughout the year. Given that this is our flagship campaign, everything we do inevitably is part of Make in Nepal. And we haven't been able to drive this message clearly.”

Another challenge, according to CNI, is that the government has not taken as much ownership as they would have hoped.

Comparing it to the Make in India campaign, Director Bhatta told NepalMinute: “For example, in Make in India, the government spends thousands of rupees to support this entire thing. And the impetus came from the Government of India. In Nepal, the impetus has come from the private sector and we have brought the government on board.”

Make in India is a campaign that was launched by the Prime Minister of India in September 2014. This initiative hopes to “transform India into a global design and manufacturing hub.

In the coming fiscal year, the government of Nepal hopes to have a joint review session with the Confederation of Nepalese Industries (CNI), where the involved parties will discuss the impact of the budget on the Make in Nepal initiative.